Manure drying

The air handling units from ITB are applied mainly for manure drying. A manure drying system can be applied to all poultry houses. With the system the manure is dried from 55% upto 75%, depending on capacities and air conditions.

Types of systems

- The mixing unit; fresh intake air is mixed in the unit with air coming from the house. The rate of mixing is controlled with register valves. The mixed air is then blown near the layer nests through air channels.

- The heat exchanger; the fresh intake air is heated by the exhaust air through a tube heat exchanger. Advantages of this systems are the easy maintenance and cleaning and the possibility of drying the manure even at a high relative humidity of the intake air. Other options with this system are heating, cooling, humidification or automatic filtration

- A loose fan inside the building, directly at the air channels. The exhaust air is sucked from the house and directly blown into the channels without any mixing or further handling.

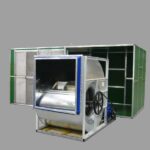

These systems are build from an anodized aluminum frame with foamed PVCsheets. The system is very stable and insulating and it can be placed both indoor and outdoor. The centrifugal fan has a double suction with high efficiency and low energy usage. It is designed with backwards bend blades so dirt does not influence the efficiency. The fan is placed on vibrationdampers and is driven with a v-belt, sound production is low.